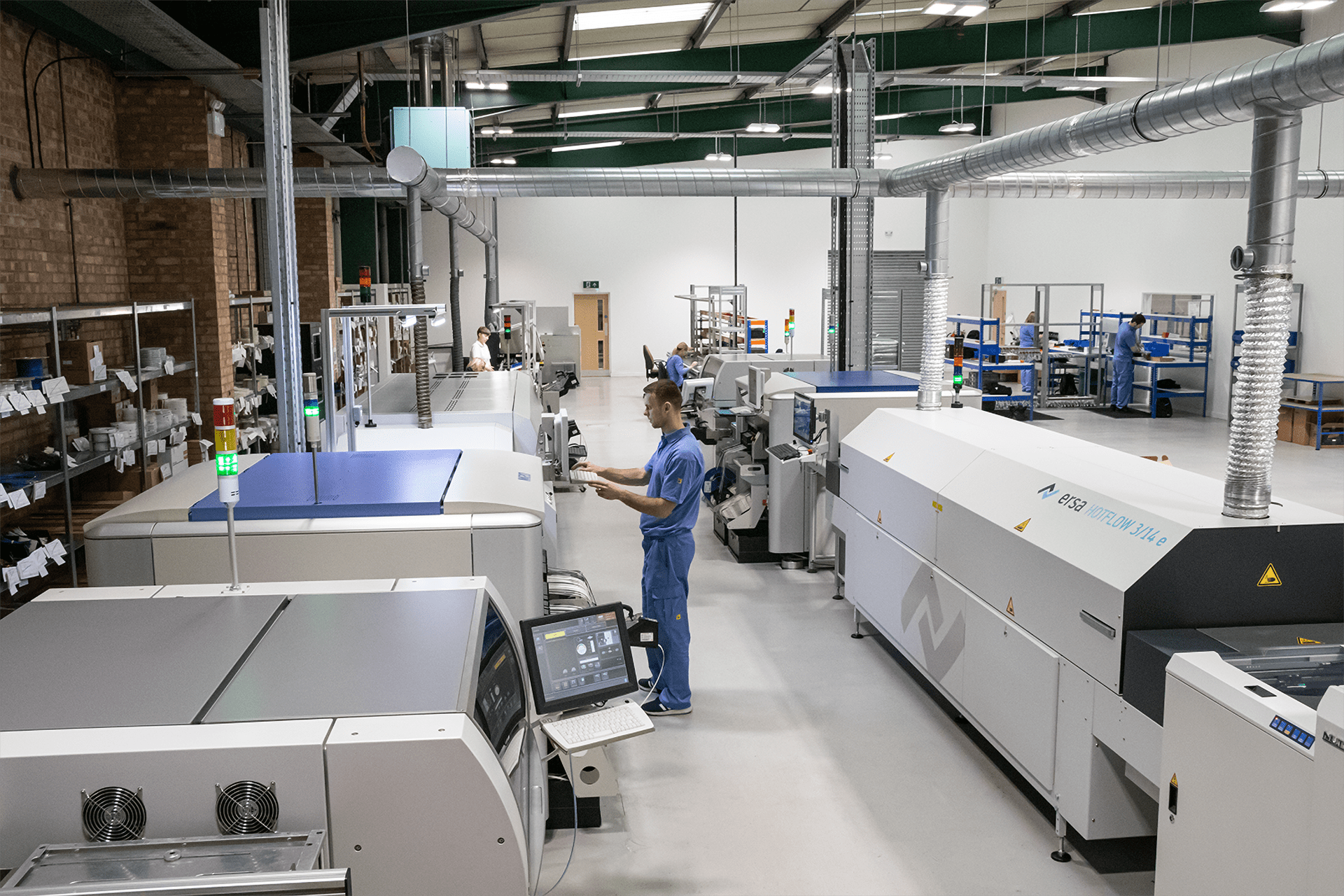

From our state-of-the-art manufacturing facilities in Telford, Tamtec provide surface mount technology (SMT) and assembly services, including 01005 (0402), fine pitch, BGA and Micro BGA.

Other services provided by Tamtec include:

- Through hole, wave soldering, PCB assembly and box build.

- 3D printing.

- Injection moulding and extrusion.

- Fabrication and welding.

- Design, prototyping and testing.

We run two surface mount lines:

Line 1 –ASM Printer, Yamaha I-Pulse M20 and Iemme Reflow.

Line 2 – ASM Printer, Yamaha I-Pulse S20 and Ersa Hotflow.

IMG_0214-min

JBP_7223

JBP_3078

JBP_3184

JBP_3336

Tamtec also utilise the latest technology:

- Double sided reflow.

- Faster assembly - Placing up to 32,500 components per hour per line.

- Large board handling up to 955 x 510mm as standard.

- Optional PCB size for LED lighting applications up to 1,330 x 510mm.

- Laser board warp detection.

- Component range std. – 01005mm up to 120L x 90W x 30mm high.

- Optional component range – 0.2 x 0.1mm up to 120L x 90W x 30mm high.

- High Feeder capacity – up to 180 x 8mm feeders.

- New 12 and 6 spindle high capacity placement head.

- Fully controllable placement force.